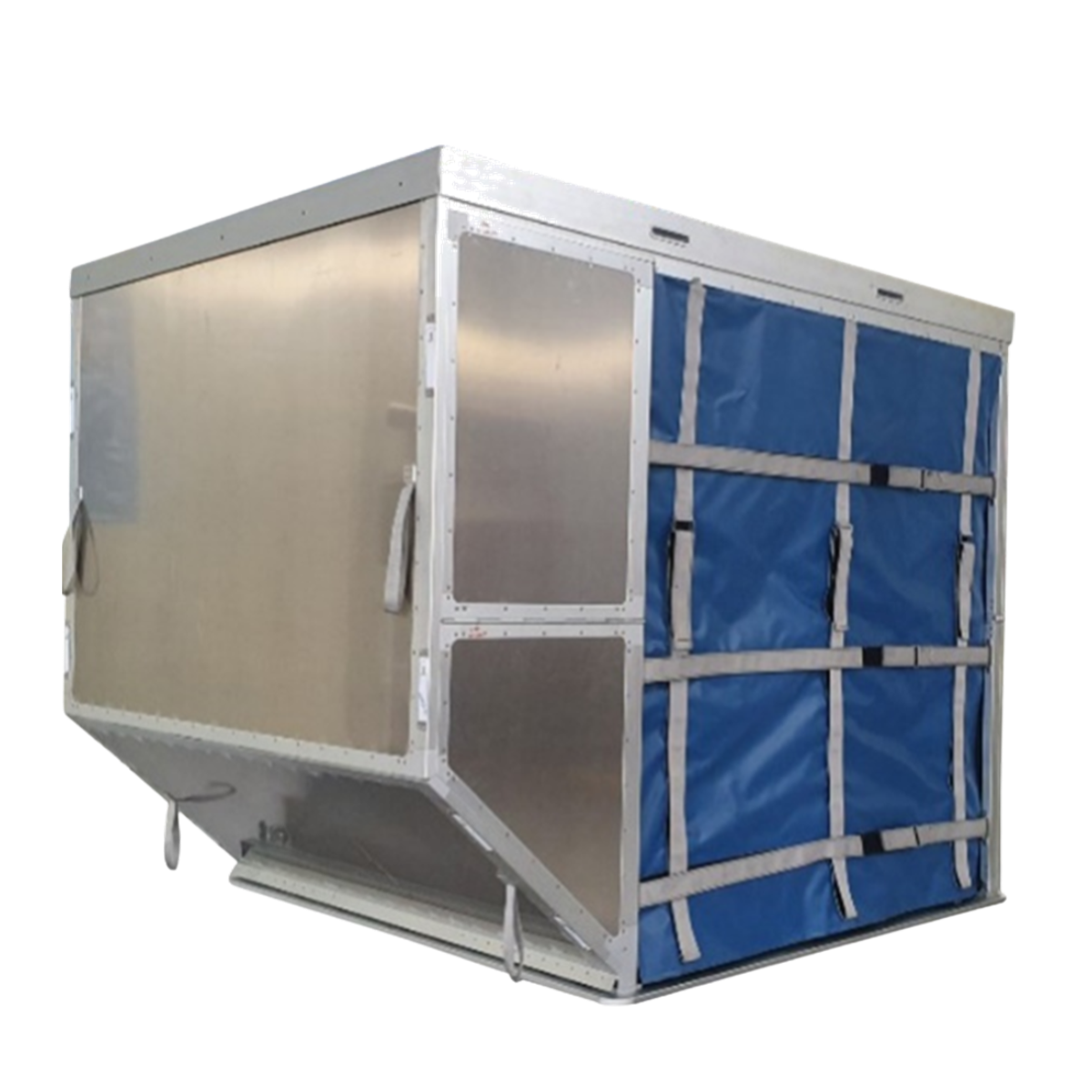

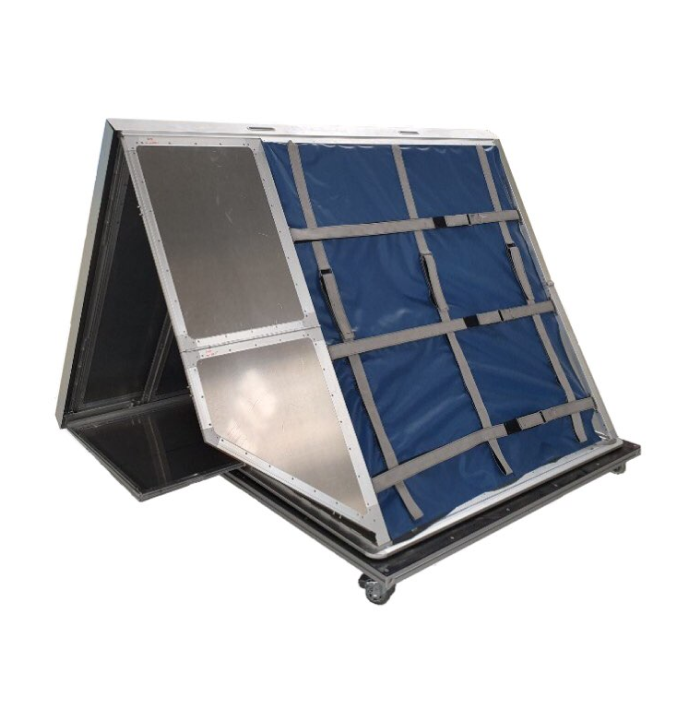

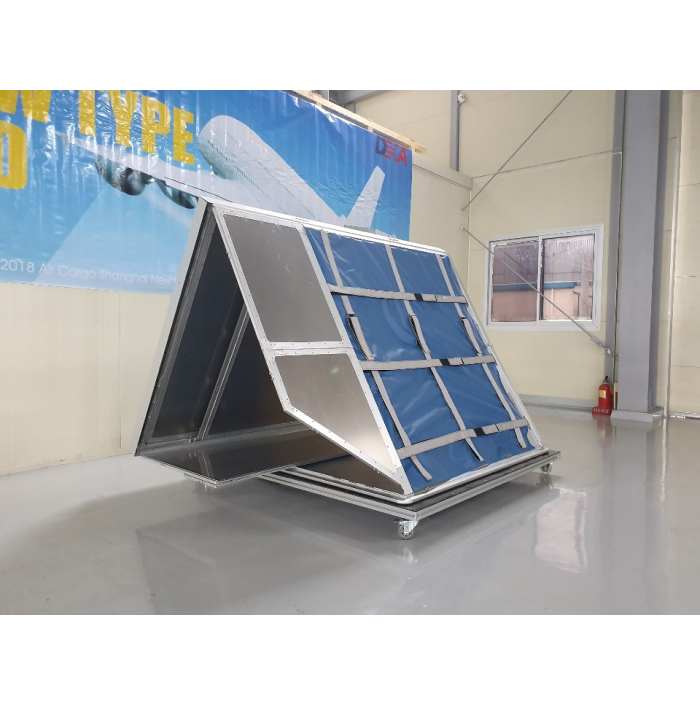

Foldtainer

Redefining Efficiency in Air Cargo

Foldtainer boasts exceptional space efficiency and durability, revolutionizing the way you transport goods. Designed for easy folding, convenient storage, and simple repairs, it leads the future of air cargo containers.

Save Your

Storage

No need to possess huge warehouse,

Able to stack up 10 to 12 units.

No need to possess huge warehouse, Able to stack up 10 to 12 units.

Time

Save your precious time for transporting and

retrieving your container.

Save your precious time for transporting and retrieving your container.

Effort

Effortlessly expand your operational capabilities with versatile and adaptable foldable containers.

Effortlessly expand your operational capabilities with versatile and adaptable foldable containers.

Resources

Conserve materials by using foldable containers that require less raw material and reduce waste. Enhance sustainability by optimizing space and fuel efficiency, leading to lower carbon emissions and a smaller environmental footprint.

Conserve materials by using foldable containers that require less raw material and reduce waste. Enhance sustainability by optimizing space and fuel efficiency, leading to lower carbon emissions and a smaller environmental footprint.

Cost

1. Significantly reduce repair costs and easily replace components, ensuring lower maintenance expenses.

2. Transport up to 91 foldtainer units in a 40ft HQ marine container, and transport up to 3.5 times more by air compared BOX-TYPE units.

1. Significantly reduce repair costs and easily replace components, ensuring lower maintenance expenses. 2. Transport up to 91 foldtainer units in a 40ft HQ marine container, and transport up to 3.5 times more by air compared BOX-TYPE units.

Why Foldtainer?

Advantages of Foldtainer.

Structural functionality and durability

High-quality parts & raw materials

Quick and Easy Repair

Full knock-down system: space efficiency

Front & Rear panel opening

Information

| Attribute | Measurements |

|---|---|

| Base Size | 61.5 in x 60.4 in (1562 mm x 1534 mm) |

| Collapsed Size | 79.0 in x 60.4 in x 6.9 in (2006 mm x 1534 mm x 175 mm) |

| Height | 64.03 in (1626 mm) |

| Roof Length | 79.0 in (2006 mm) |

| Max Gross Weight | 3500 lb (1587.57 kg) |

| Internal Volume | 153 cu ft (4.99 cu m) |

| External Volume | 162.86 cu ft (4.61 cu m) |

| Tare Weight | 220 lb (99.7 kg) |

| Certifications |

|---|

| IATA LD-3 / AKE SAE AS36100 Rev B Class |

| 2019 FAA TSO-C90d, Deviation Approval by FAA |

| Fold and Expand |

|---|

| 2 fully trained people can fold and expand it in less than 2 minutes. |

| USTAR-DKA Automation Project |

|---|

| The USTAR-DKA ULD models are revolutionizing the air cargo ULD logistics industry with their UNIQUE and NOBLE design structure. Based on cutting-edge concepts, these models prioritize safety and durability, incorporating fundamental new technologies and functionalities. Our approach offers unprecedented solutions to current challenges in the industry. By integrating AI humanoid robots in preparation for the Fourth Industrial Revolution, we have redefined ULD manufacturing and production management. |

| Key Features of the USTAR-DKA Automation Project: |

|---|

| • Innovative Design and Production: Implementing DoF actuate design principles. |

| • Foldable Air Cargo Containers: Combining foldable air cargo containers with Optimus AI for an innovative solution that addresses all challenges in the air logistics industry. |

| ULD Remote Control Operation System: |

|---|

| 1. Implementation of Mechanisms for All Models of FAA TSOA LD3 Approved Foldable Air Cargo Containers |

| 2. All Models of Foldable Automatic Air Cargo Containers |

| 3. Assembly Production Facilities for Foldable Automatic Air Cargo Containers |

| 4. Implementation of ULD Product Manufacturing through AI Robot Integration and Combination Production Systems for Foldable Automatic Air Cargo Container Assembly Lines |

| 5. Optimized Lightweight Air Cargo Containers and Mechanisms for Disassembly and Assembly |

| 6. Smart Factory Models for Shipper Containers |

| 7. Comprehensive Management System and Repair System for 40HQM |

| 8. Comprehensive Storage and Mobility Management System for 40HQM |

| 9. Assembly and Disassembly SE Production Management System for 40HQM |

| 10. Final Inspection System for 40HQM Products |

| 11. Toxic, Fire, Temperature, and Theft Control and Tracking System for 40HQM |

| 12. ULD Loss Tracking Management System |

| 13. Integrated Computer-Based Self-Management System |

| 14. Optimization of Production Inventory Management |

| References |

|---|

| AS36100 |

| AS36100A |

| AS36100B |

| AS33601 |

| AS36102 |

| Technical Standard Order |

| IATA Airport Handling Manual |

| IATA ULD Technical Manual |

| IATA ULD Regulations |

| PSCP (Project Specific Certification Plan) |

| CIP (Conformity Inspection Plan) |

| Deviation Request |

| Flammability Test |

| FAI (First Article Inspection) |

| ICA (Instructions for Continued Airworthiness) |

| RFC (Request For Conformity) |

| 1.0 Cargo Container Configuration Control |

| 1.1 Cargo Container Manuals / Quality Manuals |

| 1.1.1 Cargo Container Maintenance Manual |

| 1.1.2 Cargo Container Instruction Manual |

| 1.1.3 Cargo Container Attaching Curtain Door Instruction Manual |

| 1.1.4 Cargo Container Component Maintenance Manual |

| 1.1.5 Cargo Container Operation Maintenance Manual |

| 1.1.6 Cargo Container Supplier Quality / Contract Requirements Quality System |

| 1.1.7 Cargo Container First Article Inspection Manual |

| 1.1.8 Cargo Container Supplier Deviation Request Manual |

| 2.0 Manuals |

| 2.1 Manual Management |

| 2.1.1 Manual Currency Airworthiness |

| 2.1.1 Manual Currency Operations |

| 2.1.2 Content Consistency Across Manuals Airworthiness |

| 2.1.2 Content Consistency Across Manuals Operations |

| 2.1.3 Distribution (Manuals) Airworthiness |

| 2.1.3 Distribution (Manuals) Operations |

| 2.1.4 Availability (Manuals) Airworthiness |

| 2.1.4 Availability (Manuals) Operations |

| 2.1.5 Supplemental Operations Manual Requirements Airworthiness |

| 2.1.6 Supplemental Operations Manual Requirements Operations |